Packaging & Material Handling

We are dealing here with the contents, but also the packaging. This is certainly true in the consumer market, where packaging should trigger the consumer to buy the product it contains – or the opposite, in the case of tobacco. In addition the outer packaging should also look attractive. For example, these days many products are placed on the shelf (retail-ready) in the box, for neater presentation and easier shelf stocking.

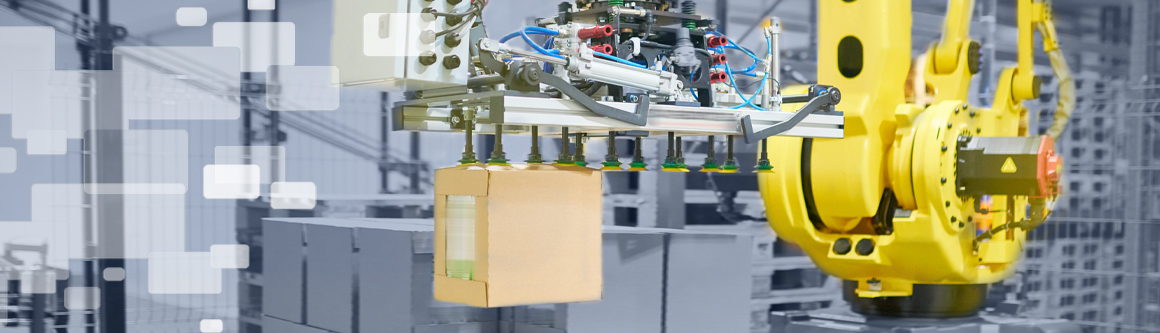

Similar developments are seen in the professional market. The importance of product imaging and packaging is increasing, and the logistics especially have to be efficient. For example, retail-ready packaging is provided with additional perforations and may not be damaged through handling. It should also not cause malfunctions during processing and must be easy to handle. This means that handling of packages, but also of products in general is increasingly becoming a critical process step. This places high demands on automation and robotisation.

This means many functional challenges being imposed on the manufacturers of packaging machines and other handling equipment. Along with this, seamless integration into complete lines is required for physical handling but also for communication with regard to control. At the same time, the machine builders and system integrators need to deliver their packaging and handling systems ever faster, as investment decisions are increasingly being made at the last minute.

All of this requires continuous innovation and the efficient organisation of the construction and installation of lines. Standardisation of components and modules contributes to that, as well as a smart logistics concept for mechanical and electrotechnical supplies. The technical value-added distributor can provide broad advice on that and of course deliver the necessary supplies and technology. This partner knows everything about the contents and the packaging.